What is dielectric strength of transformer oil?

The dielectric strength of transformer oil is also known as the breakdown voltage (BDV) of transformer oil. Breakdown voltage is measured by observing at what voltage, sparking strands between two electrodes immersed in the oil, separated by a specific gap. A low value of BDV indicates presence of moisture content and conducting substances in the oil.

How is dielectric strength of transformer oil measured?

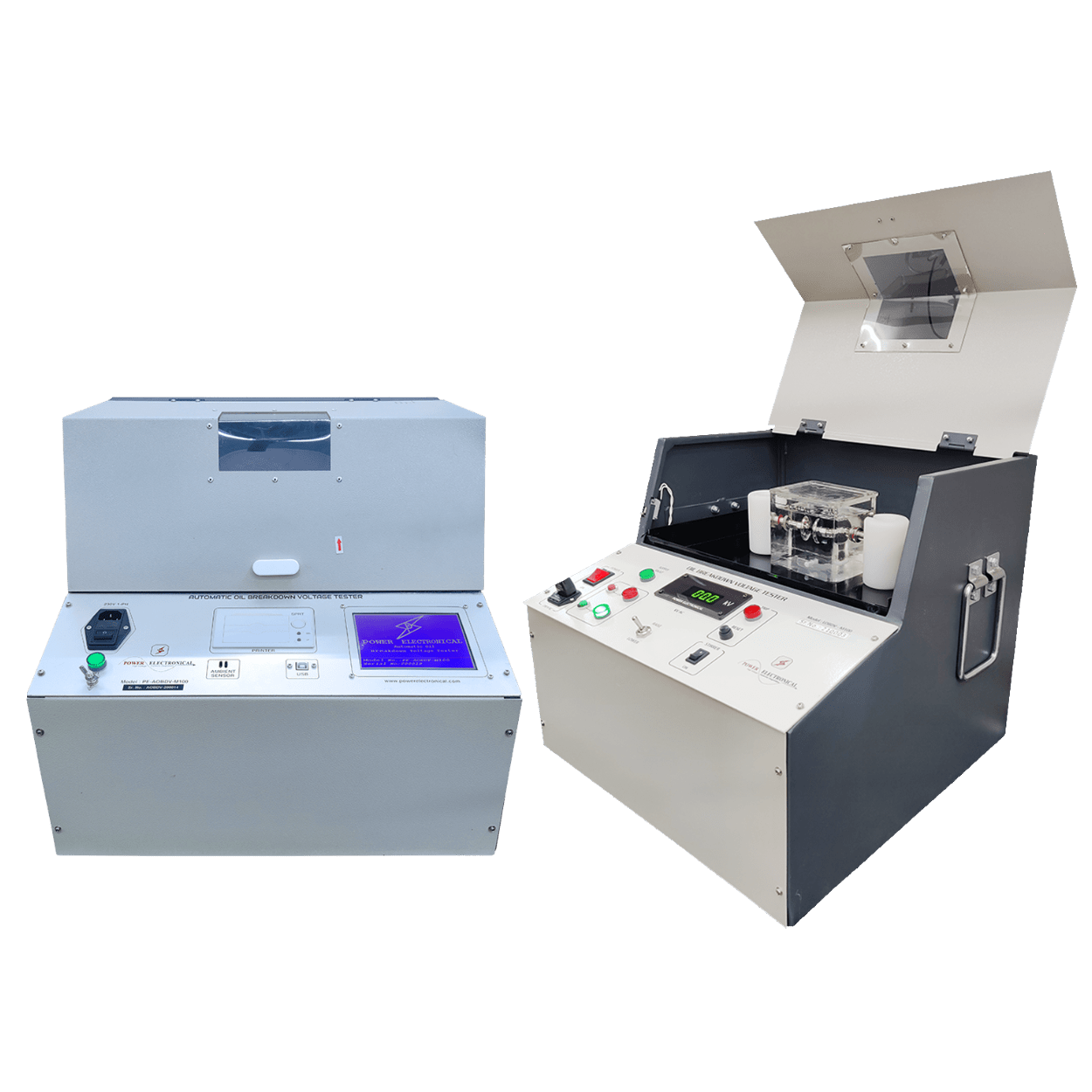

For measuring BDV of transformer oil, portable BDV measuring kit is used such as PE-AOBDV-MXXX or PE-LOBDV-MXXX. In these kits, oil is kept in a pot/chamber in which one pair of electrodes are fixed with a gap of 2.5 mm (in some kit it 4mm) between them. Then slowly rising voltage is applied between the electrodes. The rate of rising voltage is controlled and observed at which sparking starts between the electrodes. That means at which voltage dielectric strength of transformer oil between the electrodes has been broken down.

This measurement is taken 3 to 6 times in the same sample of oil, and we take the average value of these readings. BDV is an important and popular test of transformer oil, as it is the primary indicator of the health of oil and it can be easily carried out at the site.

This measurement is taken 3 to 6 times in the same sample of oil, and we take the average value of these readings. BDV is an important and popular test of transformer oil, as it is the primary indicator of the health of oil and it can be easily carried out at the site.

Dry and clean oil gives BDV results, better than the oil with moisture content and other conducting impurities. Minimum breakdown voltage of transformer oil or dielectric strength of transformer oil at which this oil can safely be used in transformer, is considered as 30 KV.

The dielectric breakdown voltage test is an important test to determine the withstanding capacity of any insulating oil or liquid. There is a degradation of transformer oils or ingress of moisture and it is necessary to test the insulating oils periodically. Break Down Voltage (BDV) test is one of the most common tests done on all Insulating fluids, but a very critical one. Breakdown Voltage Test (BDV) is a most preferred choice because it takes very less time to conduct and is a precursor to the condition of the insulating liquid, before carrying out extensive series of tests.